More than 30 years ago, ultraviolet (UV) light was successfully applied in commercial applications. Various adhesives manufacturers have developed a series of UV products for bonding, sealing, printing and so on, which are widely used in many fields such as communication, electronics, optics, printing and so on.

These products will solidify or harden (polymerize) under the irradiation of UV light (certain wavelength and intensity). Compared with traditional products, UV curing is faster, more efficient, energy saving and environmental protection. In the optical industry, three lenses are usually joined, but in most cases, two lenses are joined. UV glue was cured after the lens was bonded.

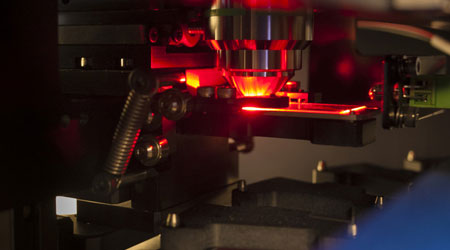

After bonding lenses with high-intensity ultraviolet light in light-curing equipment, active free radicals or ionic radicals are produced, resulting in polymerization, cross-linking and grafting reactions. Resins (UV coatings, inks, adhesives, etc.) are converted from liquids to solids in seconds (varying). At present, most of the optical enterprises mainly adopt the bonding and solidification technology as "the hardening". "This hardening" technology scheme uses Toshiba and Philips brand special UV light source (FL40S. BL and other models), fixed in the hardening cabinet, connected to the power supply, illuminated lenses for up to 4 hours to complete the glue solidification. The ultraviolet radiation intensity of this method is weak (0.6-1.Omw/cm2), and the absorbed energy of glue is small in the plain time, resulting in long curing time of glue, which requires 4 hours to cure.

During the irradiation process, the illumination can not be adjusted flexibly, which makes the curing method stylized and inflexible, and objectively limits the irradiation time of lenses. This kind of curing method wastes waiting for the production of doublet lenses. When the quality of bonded lenses is poor, the experimental results are too long to correspond in time. These factors make the doublet and solidification of lens become the bottleneck of lens processing, which seriously hinders the improvement of production efficiency and the development of enterprises.

Call us on:

Call us on:  Email us:

Email us:  R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr