1、Technical principle

The curvature radius of the aspheric lens changes with the center axis. It can be used to improve optical quality, reduce the number of optical components and reduce design costs. Compared with spherical lens, aspheric lens has unique advantages, so it has been widely used in optical instrument, image and photoelectron industry, such as digital camera, CD player and high end micro instrument.

2、Comparative advantage

a, Spherical aberration calibration

The most remarkable advantage of aspheric lenses in replacing spherical lenses is that they can correct the spherical aberration caused by spherical lenses in collimating and focusing systems. By adjusting the surface constant and the aspheric coefficient, the aspheric lens can eliminate spherical aberration to the maximum extent.Aspheric lenses (rays converge to the same point and provides optical quality) basically eliminate spherical aberrations produced by spherical lenses (rays converge to different points and leads to blurred imaging).

Three spherical lenses are used to increase the effective focal length, which can be used to eliminate spherical aberration. However, a aspheric lens (high numerical aperture, short focal length) can be realized, and it can simplify the system design and provide the light transmittance.

b, System advantages

The aspheric lens simplifies the elements involved in optical engineers to improve the optical quality and improves the stability of the system.For example, in zoom systems, 10 or more lenses are normally used (additional: high mechanical tolerances, additional assembly procedures, and the improvement of antireflection coating). However, one or two aspheric lenses can achieve similar or better optical qualities. This reduces the system size, increases the cost rate and reduces the overall cost of the system.

3、Moulding techniques

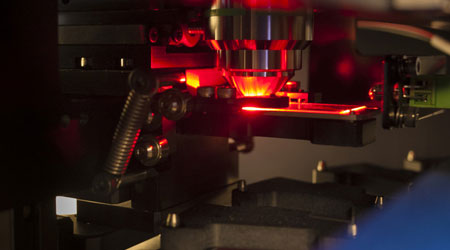

a, Moulding of precision glass

The molding of precision glass is to make the glass material heated to high temperature and become plastic, and then molded by aspheric mold, and finally gradually cooled to room temperature.At present, the molding of precision glass is not suitable for aspheric lens with diameter greater than 10mm. However, new tools, optical glass and metrology process are driving the development of the technology. Although precision glass molding at the beginning of the design has high cost (high precision mold development), but after the molding, the production of high-quality products can be split off the pre development costs. It is especially suitable for the needs of mass production.

b, Forming of precision polishing

Lapping and polishing are generally applicable to the production of monolithic aspheric lenses at one time. With the improvement of technology, the accuracy is higher and higher.The most remarkable thing is that precise polishing is controlled by computers and automatically adjusted to optimize parameters.If higher quality polishing is required, magnetorheological finishing (magneto-rheological finishing) will be adopted. Compared with standard polishing, magnetorheological finishing has higher performance and shorter time.Precision polishing molding technology need professional equipment. It is currently the first choice of sample production and small batch sample.

c, Hybrid molding technology

The hybrid molding is a spherical aspheric lens with a spherical lens as the substrate, which is cast on the surface of the spherical lens through an aspherical mould and cured by a layer of high polymer with UV light.Mixed forming is generally used the achromatic spherical lens as the base, and then a layer of aspheric surface is cast on the surface to eliminate chromatic aberration and spherical aberration simultaneously.Figure 7 is the manufacturing process of the hybrid aspheric lens. The hybrid aspherical lens is suitable for large scale manufacturing with additional characteristics (eliminating chromatic aberration and spherical aberration) .

d, Injection molding

In addition to glass aspherical lenses, there are plastic aspheric lenses.Plastic molding is the injection of molten plastics into aspherical molds.Compared with glass, the thermal stability and compressive resistance of plastics are poor. It requires special treatment to obtain similar aspherical lenses. However, the plastic aspheric lens is characterized by its low cost, light weight and easy molding. It is widely used in the fields of moderate optical quality, insensitive to thermal stability and little pressure resistance.

4、Basis of choice

All kinds of aspheric lenses have their own relative advantages. Therefore, it is very important to choose the right products for different applications. The main considerations include: batch, quality and cost.

Call us on:

Call us on:  Email us:

Email us:  R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr