Recent advancements in manufacturing techniques for elliptical flat mirrors have revolutionized the optics industry. Hyperion Optics, a leading brand in the field, has played a significant role in pushing the boundaries of what is possible with these innovative mirrors. In this blog, we will explore the latest developments in manufacturing techniques for elliptical flat mirrors and how Hyperion Optics has contributed to these advancements.

To understand the advancements made in manufacturing techniques, it is essential to first grasp the basic concept of elliptical flat mirrors. These mirrors have a unique shape that combines the features of both an ellipse and a flat mirror. The elliptical shape allows for precise focusing and directing of light, making them ideal for a wide range of applications such as telescopes, microscopes, and laser systems.

In the past, manufacturing elliptical flat mirrors was a complex and time-consuming process. Techniques such as grinding and polishing were used to shape the mirror's surface, followed by a coating process to enhance reflectivity. While these techniques yielded satisfactory results, they often came with inherent limitations, such as limited design flexibility and potential for errors in the final product.

Hyperion Optics has been at the forefront of developing innovative manufacturing techniques for elliptical flat mirrors. Our team of skilled engineers and scientists have pioneered new methods that have significantly improved the efficiency and precision of mirror manufacturing.

One such technique is utilizing advanced computer-aided design and manufacturing (CAD/CAM) software, which allows for precise control over the mirror's shape and surface. This enables the production of mirrors with customized specifications tailored to specific applications.

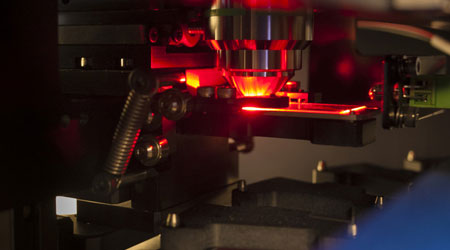

Additionally, Hyperion Optics has invested in state-of-the-art machinery and equipment to streamline the manufacturing process. Advanced polishing techniques, such as magnetorheological finishing, have been adopted to achieve ultra-smooth mirror surfaces with minimal surface irregularities and imperfections.

These recent advancements in manufacturing techniques have brought several benefits to the optics industry. Firstly, the enhanced precision in shaping the elliptical flat mirrors has allowed for improved optical performance, resulting in sharper and more focused images.

The increased design flexibility has opened up new possibilities for applications. For instance, the ability to produce mirrors with complex curved shapes has enabled the development of compact imaging systems with improved performance.

Furthermore, the improved efficiency in manufacturing has reduced lead times and costs associated with producing elliptical flat mirrors, making them more accessible to a wider range of industries.

In conclusion, recent advancements in manufacturing techniques for elliptical flat mirrors have ushered in a new era of optics technology. Brands like Hyperion Optics have significantly contributed to these advancements through their relentless pursuit of innovation and excellence. With their cutting-edge methods, precision engineering, and commitment to delivering superior products, the future of elliptical flat mirrors looks promising.

Call us on:

Call us on:  Email us:

Email us:  R&D Center: Aoti Street #68 Building 4A 405 International R&D park, Nanjing

R&D Center: Aoti Street #68 Building 4A 405 International R&D park, Nanjing

English

English  cn

cn  de

de  es

es  fr

fr