METROLOGY is a serious matter.

At Hyperion, we believe in quantitative science. Since its founding in 2008, Hyperion has continued to invest in metrology capabilities. Our QC department is equipped to inspect almost every precision optical specification. From optical component to complex lens assemblies, Hyperion employs quantitative measuring devices along every step of production to monitor and safeguard quality.

100% Inspection = Guaranteed satisfaction

Detailed

inspection reports signed off by our QA managers will accompany every

product shipment. Dimensional measurements, ZYGO interferometry reports, and

actual coating curves are standard items in a given inspection report. Every

specification on print is 100% tested before shipment to ensure what you

receive will meet or surpass your quality expectations. Interested in seeing what

is included in our standard QA report? Contact us to request for a sample inspection report.

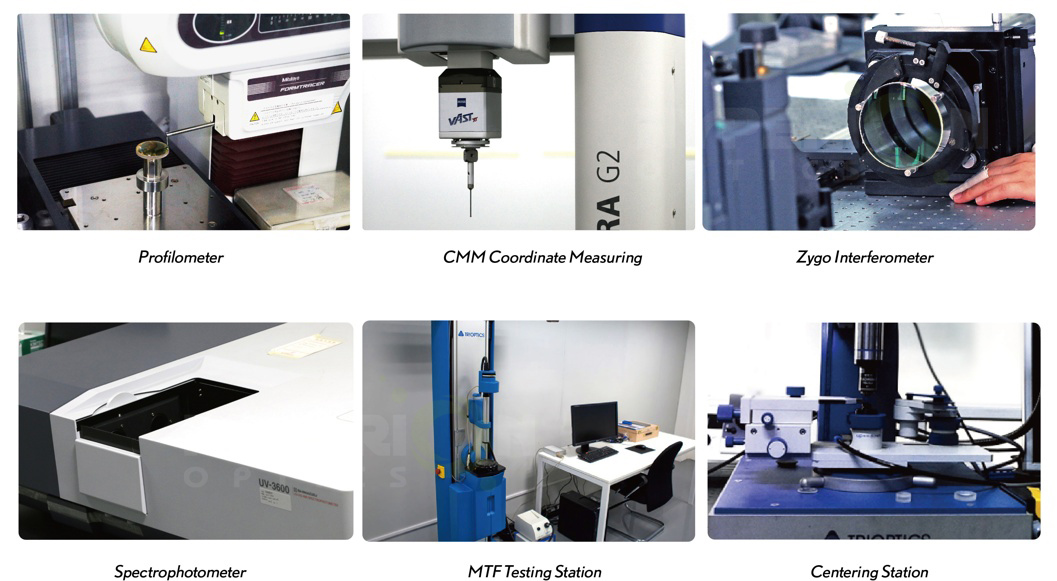

In-House Metrology

Hyperion offers a range of comprehensive metrology capabilities in standard QA procedure. Customized testing is available upon request, such as material index, dispersion testing, thermal testing, and other application-based tests. Our QA engineering team can customize an inspection plan for your specialized application needs.

1. ZYGO Verifire Interferometer

The latest ZYGO Verifire Interferometry System offers an enhanced accuracy in

optical surface measurements.

Mx™ metrology software with measurement accuracy of 1/20waves

Dynamic, contactless measurements of surface flatness

QPSI™ Vibration-Tolerant Interferometry

SmartAveraging® Technology

2. Nicolet iS 20 FTIR Spectrometer

The Thermo Scientific™ Spectrometer offers unparalleled analytical accuracy for FTIR spectroscopy, enabling us to verify the materials can meet your application needs before production begins.

Accurately detect transmission, reflection/ absorption at high spectral resolution (0.25 cm-1) and single-to-noise ratios (50,000:1)

Consistent spectral data

OMNIC Specta software, including a library of >9,000 chemical spectra

3. Mitutoyo Profiler Roundtracer

Aspheric contour/ profile measurement

SAG value and tolerance verification

Fit distance & Angle

Optical axis inclination

4. Zeiss® CMM Coordinate Measuring Station

Precise Coordinates measurements

High-speed scanning with outstanding accuracy and precision

True position

Circularity/ Cylindricity

Capability to test NUV/VIS/NIR spectrum

Ultra-wide field angle of ± 110°

Max. image height of ±23 mm

Collimator range:50mm~500mm

EFL range of the sample: 1mm~150mm

Spatial frequency: 500 lp/mm, 1,000 lp/mm

Accuracy(MTF on-axis and off-axis) ±0.02 MTF

6. Trioptics Centering Station

Generate optimal centration to each lens build

Precise wedge measurement

EFL measurement +/-0.5%

7. Mechanical Measurement

Hyperion employs a range of mechanical inspection tools such as dial gauge, vernier calipers, micrometer to accurately verify dimensional measurements of our optics. We can test dimensions between 0-300mm to an accuracy of +/-3μm. All the devices are calibrated in accordance with ISO: 9001:2015 and Chinese GB standard.

The below chart illustrates the typical inspection protocols involved with each lens component and assembly fabrication:

Hyperion’s QA engineering team goes above and beyond to proactively calculate every lens focal length to verify the product before shipment during final QA process. Each lens’ focal length will be recorded on the inspection report.

Please reach out if you have further questions about our metrology capabilities or want to customize a QA process based on your application, our engineers would be happy to help.

Call us on:

Call us on:  Email us:

Email us:  9B-4F, No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

9B-4F, No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr