Usually, the Fresnel lens is cut into a spherical surface shape in order to minimize the optical aberration of the image during imaging. The lens can better align an ideal point light source into a parallel light source.

In real life, no light source is a real point light source, but solid state light emitters such as LEDs are very small, so as long as the distance between the lens and the LED is appropriate, it can be used as a point light source. Therefore, the Fresnel lens can collimate the LED output light into parallel light.

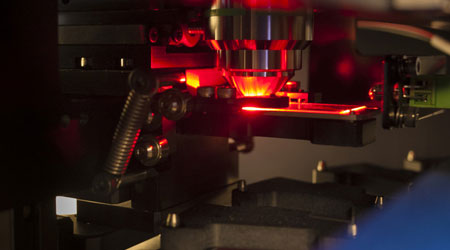

The traditional incandescent light source generates a lot of radiant heat, which limits the application of plastic optical materials very close to the light source. Since most of the heat generated by the LED is conductive, plastic optical lenses can be easily applied. When it is necessary to calibrate the beam source of the LED light source to a wider angle range, the most common method is to use a combination of a mirror and a Fresnel lens to reduce the amount of optical components used.

Fresnel lens is used for LED light distribution, which can increase light efficiency and increase brightness. Compared with the same lens and LED lamp, the focal length is different, the distance is different, the angle of the emitted light can be set arbitrarily, and single lamp or multiple array LED lamps can be designed according to requirements. It has been widely used in LED floodlights, colorful floodlights, illuminating lights, landscape lights, signal lights, and various lamps.

Advantages:

1. Using high-precision original molds, the products have high precision and good quality.

2. The product has an ultra-thin structure, an ultra-large size, and an ultra-light weight.

3. The shape of the product can be cut arbitrarily to meet the subtle differences between different customers and different products.

Compared with the traditional lens, the Fresnel lens has the advantages of large area, light weight, lower price, and being portable. It is a very widely used optical element, and its design and manufacture involve many technical fields, including optical engineering, polymer material engineering, CNC machining, diamond turning process, nickel plating process; manufacturing processes such as molding, injection molding, and casting. Therefore, the design, development and production of large-scale, high-precision Fresnel lenses have become the main direction of technological development in the production department.

Call us on:

Call us on:  Email us:

Email us:  9B-4F, No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

9B-4F, No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr