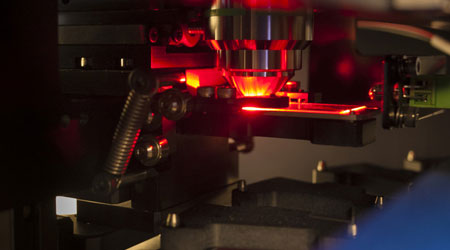

Laser technology has revolutionized various industries, ranging from telecommunications to scientific research. One critical component that enhances the performance and accuracy of laser systems is the Corner Cube Prism. In this blog, we will delve into the importance of Corner Cube Prisms and explore how these optical wonders contribute to achieving superior clarity in laser systems.

Corner Cube Prisms, also known as retro-reflectors, are triangular glass prisms with three mutually perpendicular reflective surfaces. The combination of these reflective surfaces ensures that any incident light is reflected back to its original source, regardless of the angle of incidence. Their unique design allows the light to be effectively redirected without the need for precise alignment.

These prisms are typically made from high-quality optical glass materials, such as N-BK7 or fused silica, to ensure minimal distortion and high transmission rates. The precision manufacturing process guarantees exceptional surface flatness and sharp edges, enabling precise optical alignment within laser systems.

When it comes to laser beam alignment, accuracy is paramount. Corner Cube Prisms play a vital role in achieving precise beam steering and alignment within laser systems. Due to their inherent ability to retro-reflect light, these prisms eliminate the need for complex alignment adjustments, significantly simplifying the setup process.

By redirecting the laser beam back to its source, Corner Cube Prisms ensure that the beam path remains consistent and stable, regardless of the mechanical or environmental factors. This stability is particularly crucial in applications such as surveying, metrology, and alignment systems, where consistency and accuracy are of utmost importance.

The quality of measurements in laser-based systems heavily relies on the accuracy of the beam's path. Corner Cube Prisms enhance measurement accuracy by providing a reliable and consistent reference point for laser beams.

In applications such as interferometers or laser trackers, Corner Cube Prisms enable precise distance measurement and position tracking. Their retro-reflective properties allow the incident laser light to be redirected back to the detector with minimal deviation, ensuring accurate and repeatable measurements.

With the rapidly advancing field of laser technology, Corner Cube Prism manufacturing techniques have also witnessed significant improvements. Advanced processes, such as using specialized coatings and surface treatments, enable these prisms to achieve higher reflectivity, reduce stray light, and minimize energy loss.

In addition, advancements in materials and precision manufacturing techniques have made Corner Cube Prisms more compact, lightweight, and durable. These developments have expanded the applications of Corner Cube Prisms, making them indispensable in various fields such as aerospace, defense, telecommunications, and scientific research.

Corner Cube Prisms play an integral role in laser systems, providing unparalleled accuracy, stability, and clarity. Their unique retro-reflective design allows for easy beam alignment and precise measurement, contributing to the success of applications ranging from scientific research to industrial manufacturing. As laser technology continues to evolve, we can expect further advancements in Corner Cube Prism technology, paving the way for even greater precision and clarity in laser systems.

Call us on:

Call us on:  Email us:

Email us:  R&D Center: Aoti Street #68 Building 4A 405 International R&D park, Nanjing

R&D Center: Aoti Street #68 Building 4A 405 International R&D park, Nanjing

English

English  cn

cn  de

de  es

es  fr

fr