The pentaprism deviates the lights beam by 90° through reflection of two surfaces while maintaining image parity. The deviation of the beam will not change the slight rotation of the prism, so it is useful for applications that require strict alignment. Alternative prisms include roof pentagons that reverse the parity of the image and half pentagons that deviate lights by 45°. Pentaprisms are commonly used in image mounting components and act as laser insertion prisms for advanced surveillance and ranging applications.

We usually use aluminum, silver and gold mirror coatings and epoxy protective paint on the two reflective surfaces of the pentaprism. In addition, the 22.5° incident angle of the reflective surfaces are very suitable for use in the coating of dielectric high reflectors and dichroic beamsplitters that work under wide cone angles.

The configuration of the pentaprism has a variety of options. They are excellent at beam alignment, image clarity and appearance quality. Laser or broadband anti-reflective coatings can be used on the entrance or exit surface, and protected metals and customized dielectric coatings can be used on reflective surfaces. Pentaprism can also be glued with wedge prisms or other components to create optical components. Hyperion Opticals can customize according to user needs.

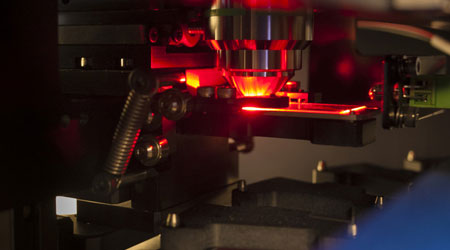

With our state-of-the-art measurement equipment and custom tools, the pentagonal prism can precisely measure the accuracy of the 90-degree azimuth beam deviation. Our high-end goniometer can use advanced modern detection technology. Combining precise custom optical and mechanical fixtures, our laser interferometer can achieve the highest resolution pentaprism measurement with an accuracy close to 0.5 arc second.

Call us on:

Call us on:  Email us:

Email us:  9B-4F, No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

9B-4F, No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr