When it comes to high-quality optical components, Hyperion Optics is a brand that stands out. Their dedication to innovation and precision has made them a leading provider of optical solutions, including the renowned f-theta objective lens. In this blog, we will explore some optimization techniques that can enhance the performance of f-theta objective lenses.

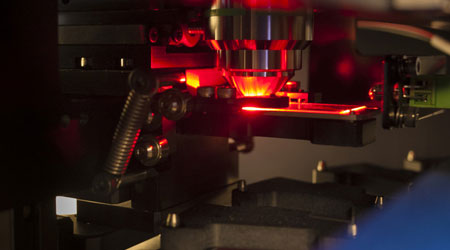

The f-theta objective lens is a crucial component in laser scanning systems and lithography machines. Its primary function is to provide a flat field image on the target surface, despite the inherent distortion caused by the incoming laser beam. The lens enables precise control over the scanning area, leading to improved accuracy and efficiency in various industrial applications.

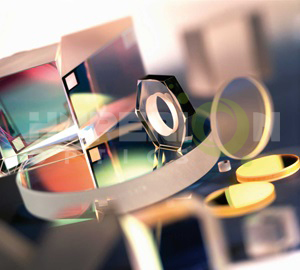

To optimize the performance of f-theta objective lenses, several design considerations must be taken into account. First and foremost is the selection of lens materials. Hyperion Optics utilizes high-quality materials with low dispersion to ensure minimal chromatic aberration. This choice is essential for achieving accurate image reproduction across different wavelengths of the laser beam.

Another critical aspect of design optimization is the choice of lens shape and arrangement. Hyperion Optics employs advanced design software and techniques to fine-tune the lens profile, optimizing its performance for specific applications. By carefully adjusting parameters such as asphericity and numerical aperture, the f-theta objective lens can deliver superior image quality and minimal distortion.

One of the key challenges in lens design is mitigating unwanted reflections that can degrade image quality. Hyperion Optics employs state-of-the-art coating technologies to minimize surface reflections. These anti-reflective coatings are carefully designed to match the refractive index of the lens material, maximizing light transmission and reducing ghost images and flare.

Moreover, additional coatings such as scratch-resistant and hydrophobic coatings can enhance the durability and usability of the f-theta objective lens. These coatings protect the lens against damage caused by environmental factors, ensuring long-term performance and reliability.

To ensure the optimum performance of f-theta objective lenses, precision manufacturing is crucial. Hyperion Optics employs advanced manufacturing techniques, including diamond turning and CNC milling, to achieve tight tolerances and smooth surfaces. This level of precision guarantees minimal wavefront distortion and high-resolution imaging capabilities.

Quality assurance is another critical aspect of optimization. Hyperion Optics adheres to stringent quality control procedures, including rigorous testing and inspection at every stage of the manufacturing process. This attention to detail ensures that each f-theta objective lens meets the highest standards of performance and reliability.

Hyperion Optics' commitment to innovation and precision makes their f-theta objective lenses a top choice for demanding applications in laser scanning systems and lithography machines. Through carefully considered design optimizations, advanced coating techniques, precision manufacturing, and thorough quality assurance, Hyperion Optics delivers lenses with exceptional image quality, minimal distortion, and outstanding durability.

In the ever-evolving field of optics, the f-theta objective lens continues to play a pivotal role in enabling precise and accurate imaging. Thanks to Hyperion Optics' continuous pursuit of excellence and optimization techniques, their f-theta objective lenses are at the forefront of innovation, satisfying the most demanding requirements of industries worldwide.

Call us on:

Call us on:  Email us:

Email us:  9B-4F, No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

9B-4F, No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr