In today's rapidly developing technological era, various advanced detection technologies are emerging, and sapphire lens endoscope technology is undoubtedly a shining star among them. It demonstrates outstanding performance in both medical and industrial fields, providing humans with numerous convenient and precise detection solutions.

The optical performance of sapphire lenses endoscope technology is exceptional. Sapphire has a very high transparency and refractive index, which means that when light passes through the sapphire lens, there is almost no loss. In medical scenarios, such as during gastroscopy, doctors can clearly see the fine tissue structures inside the human body and precisely locate lesions through the sapphire lenses endoscope. In the industrial field, for internal pipe inspections, it helps engineers clearly judge wear and crack conditions. This high-definition, clear imaging effect is a core advantage of sapphire lenses endoscope technology.

Moreover, the wear resistance of sapphire lenses endoscope technology is also outstanding. Sapphire has a Mohs hardness of 9, second only to diamonds. During actual use, endoscopes often come into contact with various surfaces, causing friction and scratches. The sapphire lenses endoscope, with its high hardness, can effectively resist external scratches. In medical gastroscopic examinations, it can maintain the smoothness of the lens surface, avoiding image blurriness due to frequent use. In industrial pipe inspections, it can work stably even against rough inner walls.

Sapphire lenses endoscope technology is widely applied in the medical field. Besides the aforementioned gastroscopy, it also plays a vital role in laparoscopic surgery. In complex laparoscopic surgeries, sapphire lenses endoscopes do not trigger an immune rejection reaction in the human body because they have good biocompatibility. Additionally, they can provide stable and clear images, allowing doctors to focus on diagnosing and treating diseases. This has immeasurable value for ensuring patient health and the success rate of surgeries.

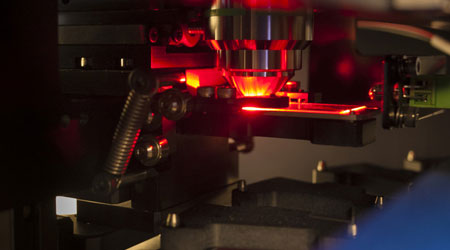

In the field of industrial inspection, sapphire lenses endoscope technology also holds an important position. For example, in the internal inspection of chemical production equipment, its chemical stability allows it to work stably and provide accurate imaging in acidic and alkaline corrosive environments, helping to detect potential equipment faults in time. In high-temperature environments such as aerospace engine manufacturing inspections, the high-temperature resistance of the sapphire lenses endoscope ensures it can work normally, greatly improving inspection efficiency and accuracy.

Compared to ordinary endoscopes, sapphire lenses endoscopes have significant advantages in several aspects. The lens material of ordinary endoscopes is mostly optical glass or plastic, which has limitations in scratch resistance and durability. The high hardness and wear resistance of sapphire lenses endoscopes allow them to maintain clear imaging quality for a long time. In terms of image quality, sapphire lenses endoscopes can provide more detailed image details and perform better in low-light environments.

With its advanced optical performance, wear resistance, chemical stability, and biocompatibility, sapphire lenses endoscope technology has become an indispensable revolutionary force in the medical and industrial detection fields. As technology continues to develop, sapphire lenses endoscope technology will undoubtedly play a greater role in more areas.

Call us on:

Call us on:  Email us:

Email us:  9B-4F, No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

9B-4F, No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr