Hyperion

Optics has over a decade of experience in optical and mechanical

design, manufacturing, and

optical assembly. With

the rapid growth in the photonics market and an increasing demand for

precision and accuracy, we have continued to upgrade our fabrication technology in order to better serve the optics community.

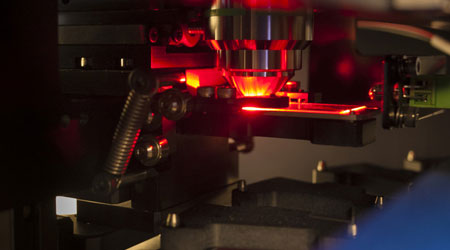

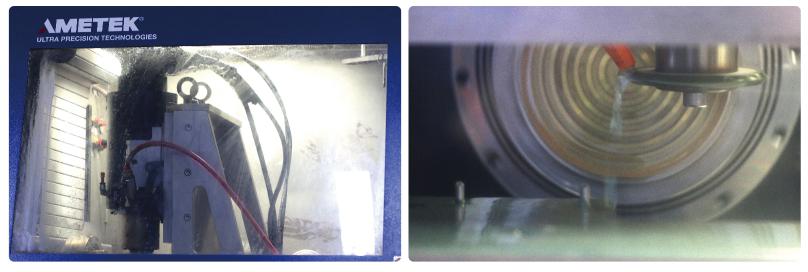

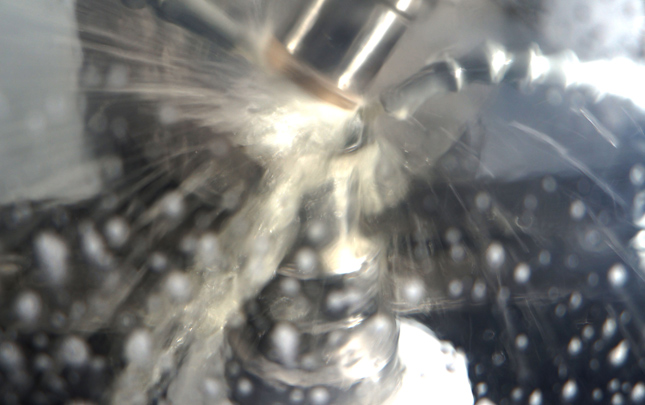

We have expanded our fabrication capabilities through employing skilled optics technicians and investing in advanced devices and

equipment. A few examples include the Optotech® machining and polishing station and the Ametek® aspherical machining device. On

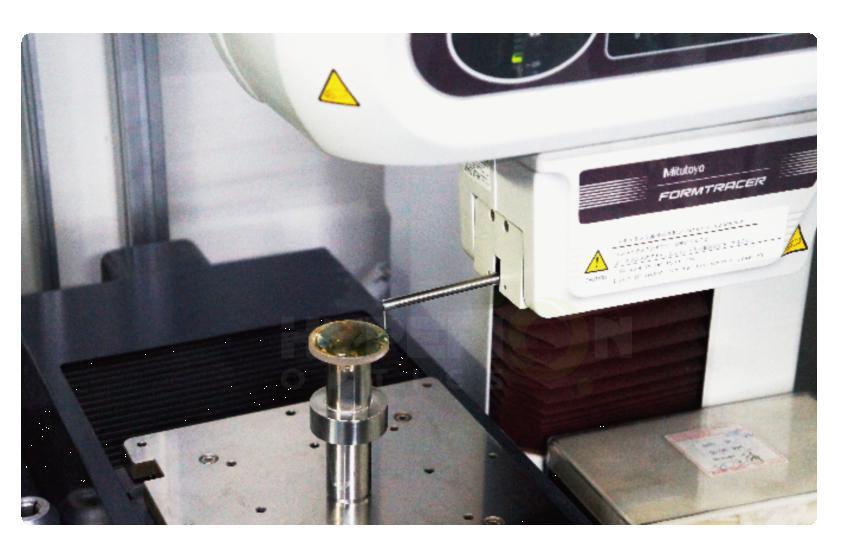

the metrology side, we are

equipped with the latest Zygo Verifire™ interferometer and MTF testing

station. From manufacturing to inspection, we believe that our

value lies in the reliability of our technology and the talents of our people.

Our

optical and engineering team consists of 15 optical experts who have

expertise and familiarity with high-end applications. Our engineers’ specialty and understanding of the optical system can ensure that your needs would be fully understood and

met. We are proud of our professional customer

service that offers

full support throughout the products’ life cycle.

Our production team has been serving our loyal customers from R&D to production projects by consistently delivering excellent quality parts. Through projects large and small, our team has grown mature and vigilant in averting potential production risks, which resulted in significant cost-savings for our customers. Our engineers invest a considerable amount of time in initial consultation to go over every optical specification. This process helps ensure that the tolerance distribution is appropriate for the given application, and can avoid unnecessary yield loss and overly-tight specification that drives up the production cost.

Over the past 12 years, Hyperion has built a rich

portfolio of successful client stories. In this growing process, we have developed a bullet-proof process that guarantees our clients in reaching their optical goals. During quotation and prior to production, our team conducts careful

review and specs examination to avoid production pitfalls. In many cases, our suggestions have successfully optimized the optical design for manufacturability and cost-savings.

For instance, it is our standard procedure to simulate the aspherical equation during the RFQ process to ensure that there are the design is manufacturable. This step also helps prevent potential failure prior to actual production. For aspherical designs that we are not confident about, we

offer free trial on low-cost material for feasibility testing to understand and study the production challenge.

Besides improving our fabrication technologies, we continue to uphold and take pride in our conventional methodology that involves high-speed polishers and machinery. With our outstanding production staff and metrology procedure, we are confident to deliver high-quality precision optics for you and your institutions.

Call us on:

Call us on:  Email us:

Email us:  R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

R&D Center: 9B-4F 401,No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr