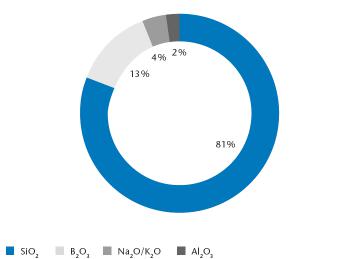

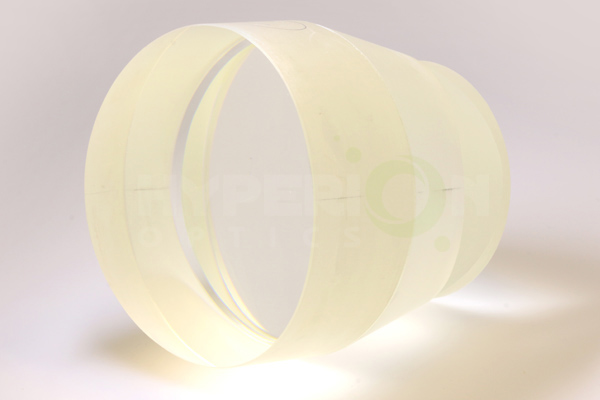

Borosilicate Windows are ideal for high temperature and harsh environment applications. With its excellent shock and thermal resistance property, borosilicate window products can maintain flatness in different environmental conditions.

Unlike common borosilicate that is drawn flat, is produced by a float technique that yields superior surface flatness — typically 4 - 6λ per inch. For more information per material property, please refer to Schott official brochure.

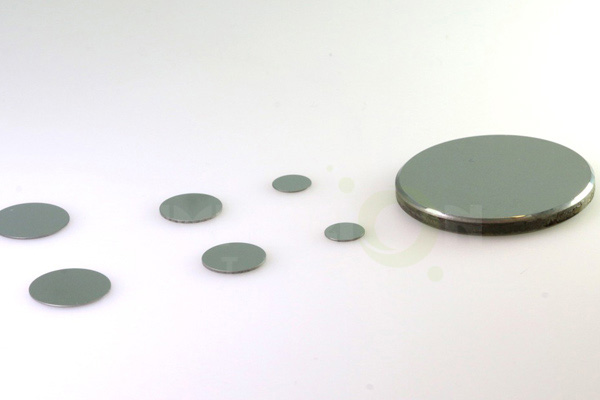

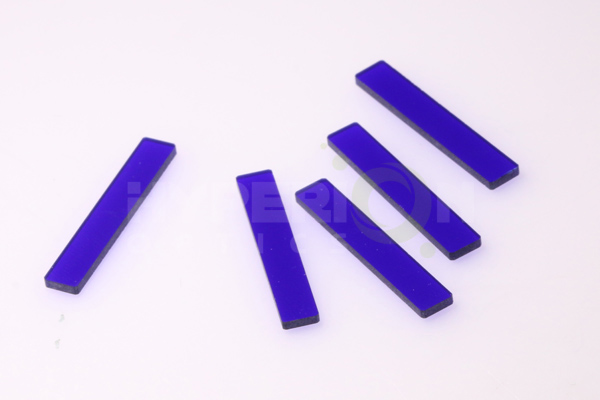

Hyperion Optics orders directly from Schott, offer two grades of custom borosilicate or equivalent windows, float grade which are cut from standard float sheet material and polished grade which are further intensively polished for better flatness and surface quality according to application requirement. We have been providing our standard and custom optical window for filter, first surface mirrors, protection windows utility.

Please check our precision grade and thickness available.

|

Standard Thickness |

|

|

CT (mm) Tol (mm) |

CT (mm) Tol (mm) |

|

0.70 ± 0.05 |

8.00 ± 0.30 |

|

1.10 ± 0.05 |

9.00 ± 0.30 |

|

1.75 ± 0.05 |

11.00 ± 0.30 |

|

2.00 ± 0.05 |

13.00 ± 0.30 |

|

2.25 ± 0.10 |

15.00 ± 0.50 |

|

2.75 ± 0.10 |

16.00 ± 0.50 |

|

3.30 ± 0.20 |

18.00 ± 0.50 |

|

3.80 ± 0.20 |

19.00 ± 0.50 |

|

5.00 ± 0.20 |

20.00 ± 0.70 |

|

5.50 ± 0.20 |

21.00 ± 0.70 |

|

6.50 ± 0.20 |

25.40 ± 1.00 |

|

7.50 ± 0.30 |

|

|

Polished Borosilicate Windows |

COMMERCIAL GRADE |

FACTORY STANDARD |

PRECISION GRADE |

|

Diameter Tolerance(mm) |

±0.05 |

±0.03 |

±0.0125 |

|

Center Thickness(mm) |

±0.01 |

±0.03 |

±0.025 |

|

Parallelism (Arc min) |

6 |

<3 |

<1 |

|

Cosmetic(MIL-C-13830A) |

100-80 |

40-20 |

10-5 |

|

Figure Tolerance inλ(Pow/irreg) |

3 - 1 |

2 - 1/4 |

1 - 1/10 |

|

Coating (T% avg) |

96-98% |

99% |

99.5% |

|

Materials |

Borosilicate Glass |

||

Call us on:

Call us on:  Email us:

Email us:  9B-4F, No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

9B-4F, No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr