Aspherical lenses have revolutionized the field of optics, enabling the production of lenses with exceptional performance and unparalleled precision. Among these, GE aspherical lenses have gained significant recognition for their unique manufacturing process. In this article, we will delve into the intricacies of manufacturing GE aspherical lenses, shedding light on the advanced techniques employed by Hyperion Optics.

GE aspherical lenses are widely acclaimed for their ability to correct various optical aberrations, enabling superior image quality. Unlike conventional lenses, GE aspherical lenses possess non-spherical surfaces that contribute to better focusing capabilities and reduced distortions. This manufacturing innovation has led to significant advancements in a range of applications, including imaging, medical devices, and industrial machinery.

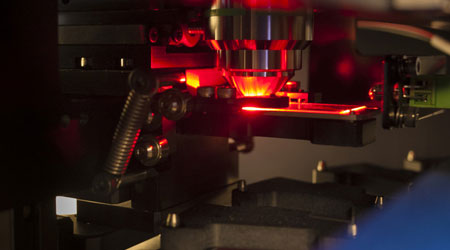

The core manufacturing process of GE aspherical lenses lies in precision molded glass techniques. Hyperion Optics utilizes cutting-edge technology and state-of-the-art equipment to fabricate intricate molds for aspherical lens production. The molds are carefully designed utilizing computer-aided design (CAD) software, ensuring the desired lens shape and specifications.

GE aspherical lenses often require multi-element designs, meaning several aspherical surfaces are encompassed within a single lens. The molds for such lenses need to be meticulously crafted to guarantee their accurate replication during production.

The choice of glass composition is a critical factor in the manufacturing process of GE aspherical lenses. Hyperion Optics extensively researches and selects suitable glass materials that match the specific optical properties required for each lens design. The selected glass must exhibit high homogeneity, low dispersion, and excellent transmission across the desired wavelength range.

Once the glass materials are determined, they undergo a series of evaluations to ensure their compatibility with advanced grinding and polishing techniques. The objective is to achieve optimum surface quality and tight tolerances, enabling the lenses to deliver uncompromised performance.

After the molds are prepared and the glass composition is finalized, Hyperion Optics employs precision machining techniques to shape the GE aspherical lenses. This process involves grinding and polishing the lenses to meet the exacting specifications required for optimal performance.

Throughout the manufacturing process, rigorous quality assurance measures are implemented to guarantee the accuracy, surface quality, and dimensional precision of each lens. Hyperion Optics utilizes advanced metrology systems, such as interferometers and profilometers, to thoroughly inspect the lens's form, surface finish, and overall quality.

GE aspherical lenses manufactured by Hyperion Optics represent a pinnacle of optical precision and innovation. By utilizing cutting-edge technology and expertise, Hyperion Optics produces GE aspherical lenses that correct aberrations, improve image quality, and offer unmatched performance in various applications. Understanding the intricate manufacturing process behind GE aspherical lenses enhances our appreciation for the technological advancements driving the field of optics forward.

Call us on:

Call us on:  Email us:

Email us:  9B-4F, No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

9B-4F, No.1 Qingnian Road Liando U Valley,Yuhua International Wisdom Valley, Nanjing, 210039 China

English

English  cn

cn  de

de  es

es  fr

fr